|

Guangzhou Kinga Auto Parts Industry Manufacture Co., Ltd

|

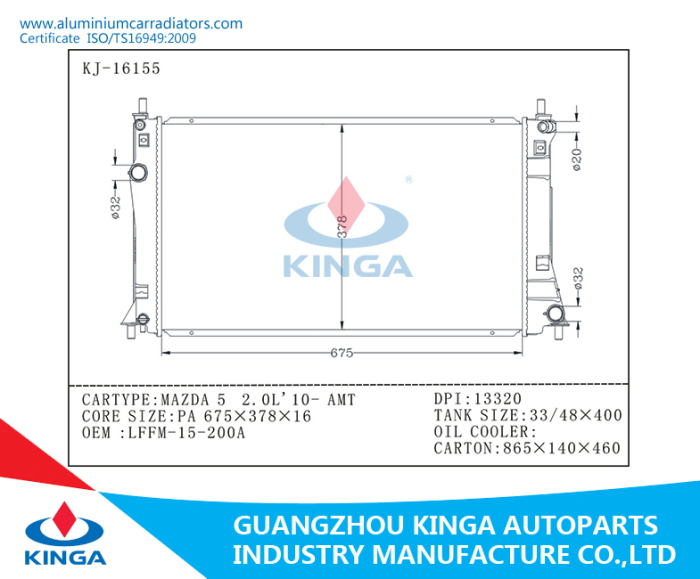

Mazda Aluminum Car Radiator LFFM-15-200A

| Payment Terms: | T/T,L/C |

| Place of Origin: | Guangdong, China (Mainland) |

|

|

|

| Add to My Favorites | |

| HiSupplier Escrow |

Product Detail

Mazda Aluminum Car Radiator

Car make MAZDA 5 2.0L 10-AMT

Aluminum Core plastic tank

OEM LFFM-15-200A

DPI 13320

Kinga Radiator,Clam down engine

Aluminum Car Radiatir for MAZDA 5 2.0L 10-AMT (LFFM-15-200A)

Detail information for Mazda Aluminum Radiator

| Factory Part No. | KJ-16155 |

| OEM | LFFM-15-200A |

| DPI | 13320 |

| Materail | Aluminum core/Plastic tank |

| Core size | 675*375.5*16mm |

| Tank size | 33/48*400mm |

| Carton size | 865*140*460mm |

| Car make | MAZDA 5 2.0L 10-AMT |

| Warray | One year |

Specifications for Kinga Radiator

1. Competitive price

2. Best quality and service.

3. Multiple finishing techniques.

4. Bran new and high durability and long natural life.

5. Command a ready market at home and abroad.

6. More than twenty years experience of producing and sale auto parts and has high reputation at home.

7. Quick delivery.

8. Light weight and low noise.

Trade information

Trade Terms | FOB ShenZhen |

Payment Terms | L/C T/T, Western Union |

Payment Condition | 30% deposit in advance, 70% balance before delivery |

Delivery Time | 30-40 working days after Money received |

Packing | Neutral packing / Foam Corner Protector / Blister Packing / Cardboard Protector |

Shipping | By sea |

Min-order | 30PCS |

warranty. | One year |

Fob price | We will quote you the Fob price after you confirm the Model radiator you want and how many |

Company Information

Guangzhou Kinga Auto parts Manufacture Co.,Ltd. was founded in 2003.Our factory is specializing

in the manufacture and export of radiator& condenser&auto parts&hardware for more than 20 years.

Aluminum Radiator workshop

Our Aluminum tank production Department has set of professional equipment production line for

"vehicle engine radiator cooling system" to manufacture more than 3,000 various products for

aluminum radiator used by different types of vehicles and engineering machines

Stamping Department

It has professional production equipment,including 30 presses,hydraulic ,cutting shears and other equipment,

which can produce stretching stamping parts,large stamping parts and precision stamping parts,etc.

Mold workshop

It has three sets of large and small CNC vertical machining centers and more than 40 various equipment.We

have the CAD/CAM network integration system for process design and mold making.The mold workshop

manufacture the metal stamping dies,injection molds,die casting molds,all fixtures,appliances for molds and

other precision molds.We design the mold for kinds of auto radiator.

Injection Molded parts production Department

It has 10 large and small injection molding machines ranging for 80T to 2000T,which can inject PC,PMMA,PA,

PE,PVC,ABS,AS,PP and other engineering plastics and can produce automotive plastic parts ( front and rear

protection bars,grilles,interior parts,automotive lighting pastic parts,and plastic goods of various of vehicles).

Condenser workshop

With high-tech and excellent equipment, the workshop is capable to undertake production and manufacture of indicated aluminum radiators of various automobiles and construction machinery with an annual output of

600 thousand, that is estimated to exceed 1 million in future. Kinga is striving to grow into an OEM

heat ex-changer manufacture from a post market enterprise.

Technology Development Center

It has professional engineering laboratory quipment for detectiong.Trough continunous technological

transformation and continuous innovstion.it improves the product technical indicators and continuously

improved product grade.

Company Shipping Area

Your waiting time reduce to Minimum,it can be delivered in the shortest time as long as the order is delivered

Your waiting time reduce to Minimum,it can be delivered in the shortest time as long as the order is delivered

to Kinga.The Key is that we have a VNA Narrow aile Racking system.We guarantee you can get the highest

quality material storage,preparation and adequate minimum safety stock.In this way,we can ensure that you

get complete in the shortest possilbe delivery time accessories.

Welcome to inquiry and Make orders.